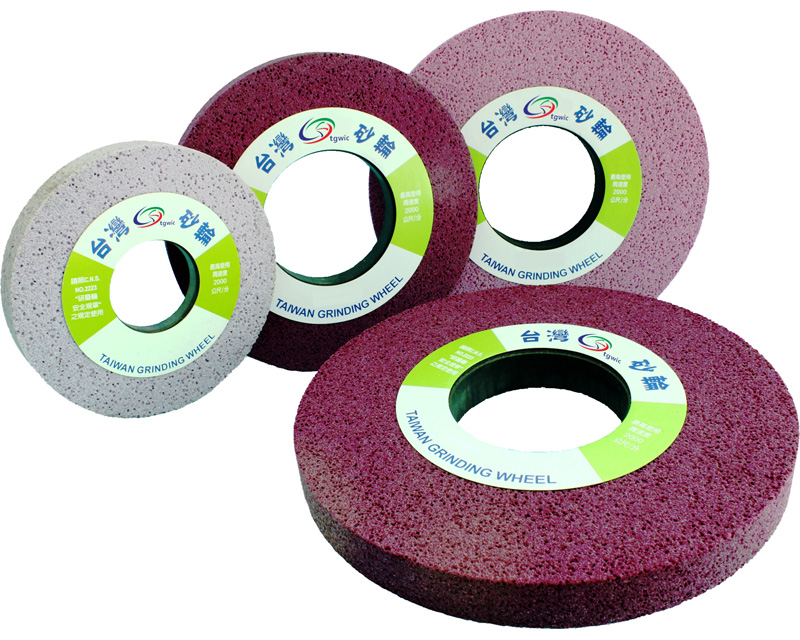

SURFACE, FORM, CREEPFEED GRINDING

Surface grinding is the grinding of flat surface in which the wheel moves past the workpiece in a flat plane, or vice versa. Surface grinding applications range from heavy rapid stock removal, to precision contour grinding. By means of appropriate abrasives mixed with optimum bond, these wheels are versatile and suitable for various materials. High efficiency, stable & high precision for size control, good free cutting ability and long dressing intervals. If used with our proprietary “controlled porosity” technology, high porosity structure (structure: W) can be imparted into the wheels to further achieve higher removal rate.

Applications

• Molds and dies. Ex: Molds for pressing, plastic injection. Casting molds for aluminum, zinc, magnesium.

• Mechanical parts used in sewing & knitting machines.

• Machine tool: slideway, guideway, slot, linear guideway & block.

• Sharpening knives, blades, razors and cutlery.

• Producing flat stock.

High Porosity Structure for Surface Grinding: DA, PA

High Porosity Structure is developed under our proprietary technology--controlled porosity. It is mainly used for hard-to-grind materials as well as heat sensitive materials, Ex: hardened steel, Inconel, nickel based alloy, cobalt based alloy and stainless steel. The free cutting ability and heat dissipation effect are very good. It’s suitable for higher depth of cut or higher removal rate such as creepfeed grinding.

PA: for medium to heavy removal rate

DA: for heavy removal rate

Features |

Benefits |

|---|---|

High Porosity |

• Increased chip clearance and maximum coolant flow • Decreased wheel loading • Cool cutting--wet or dry in heat sensitive applications |

Durable Bond/p> |

• Increased grain holding strength • Less dressing and longer wheel life |

Higher Depth of Cut |

• Increased grinding efficiency ․Consistent cutting ability at high removal rate |

Applicable Material & Wheel Specification and Sizes

Applicable Material |

Grit Sizes |

Sizes |

Remark |

|---|---|---|---|

SKD, SCM, carbon steel, SUS, and other various hardened steels as well as difficult to grind materials. |

30 |

D: ø100 ~ ø 610 mm T: 19 ~ 150 mm |

The proprietary “high porosity structure” has good heat dissipation and free cutting ability. It’s applicable to higher depth of cut and heavy removal rate. |