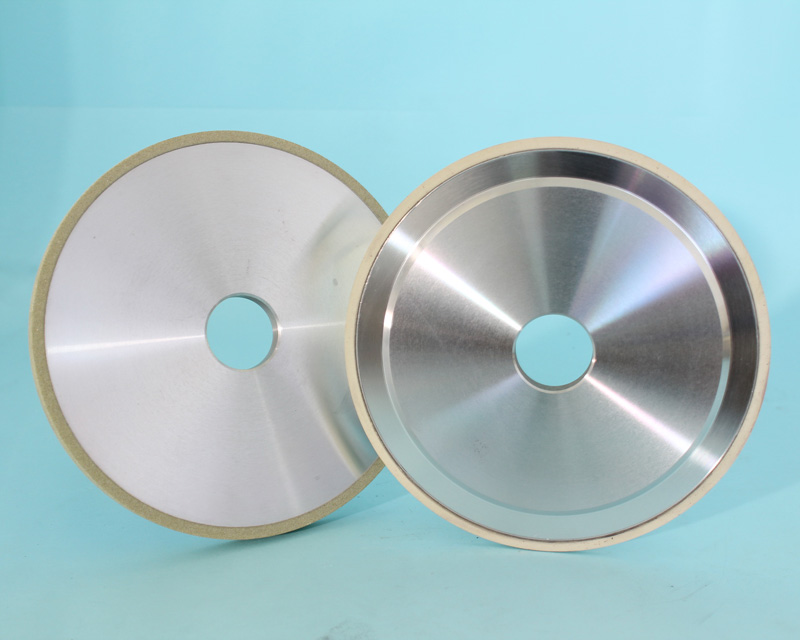

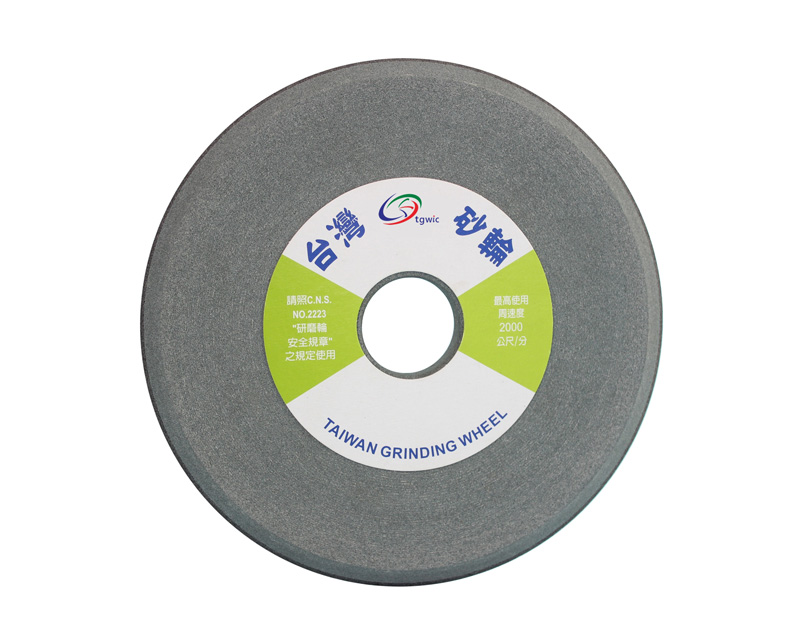

Surface, Form, Creepfeed Grinding-Vitrified Bond Precision Wheels

Features

• Low grinding resistance, stable size accuracy, good finish

Optimum combination of abrasive and bond help easy chip clearance, stable size control and finish.

• One wheel for both rough and finish grinding

By means of change of dressing parameters, one wheel can be used for both rough and finish grinding in order to meet different requirements of roughness and removal rates.

• Easy for dressing

Single point diamond or impregnated dressing tools can be used for dressing.

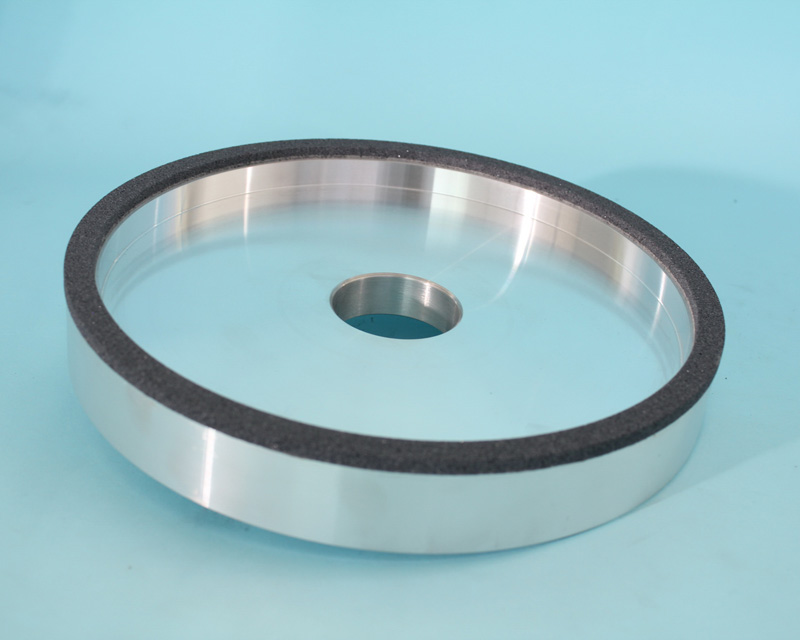

• Excellent corner holding for form grinding

Can be custom made for fine grit size and small corner while still maintaining good cutting ability.

• Strong bond holding strength and high porosity, very suitable for creepfeed grinding

With the very high hardness and thermal conductivity of superabrasives, when used in creepfeed grinding, the wheels will greatly reduce the effect of grinding heat induced to the workpiece especially suitable for materials with low thermal conductivity such as aerospace materials.

Applications for Vitrified Bond CBN Wheels

• Injection system parts

• Rocker arm form grinding

• Molds and dies

• Electric clippers and razors (vertical spindle)

• Linear guideway surface and form grinding

• Aerospace parts creepfeed grinding

• Difficult-to-grind materials creepfeed grinding, such as Inconel, nickel based and cobalt based alloy, stainless steels

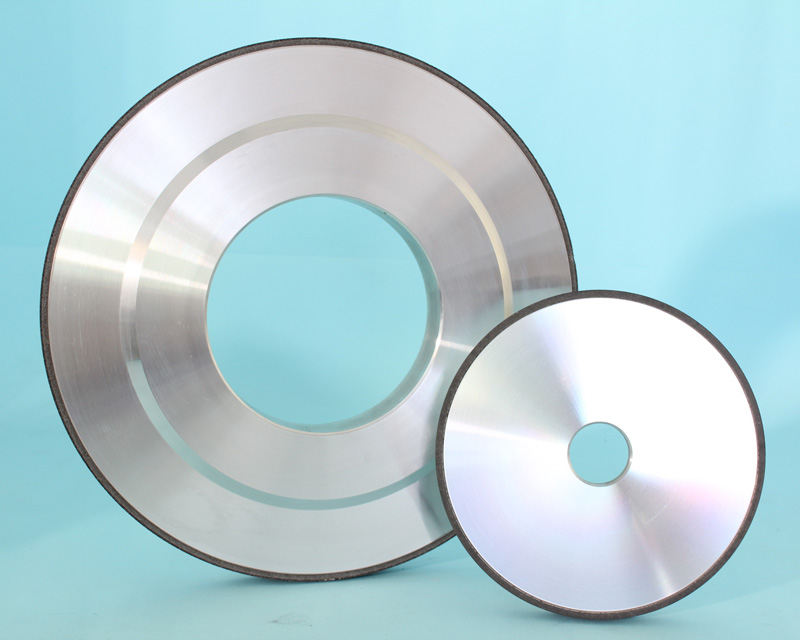

Applications for Vitrified Bond Diamond Wheels

• Tungsten carbide punch molds

• Wear resistant parts: PCD (polycrystalline diamond) and PCBN (polycrystalline CBN), monocrystalline diamond

• Tungsten carbide and cermet inserts

• Quartz products

• Silicon wafer back grinding

• Precision ceramic parts: aluminum oxide(Al2O3), zirconia(ZrO2), silicon carbide(SiC), silicon nitride(Si3N4)