External Cylindrical (OD), Centerless and Peel Grinding

Features

• High thermal conductivity

Diamond and CBN both have higher conductivities than other materials. Along with the existing of porosity and chip clearance space, lower grinding resistance can be achieved. Therefore, the temperature during grinding is lower and the occurance of burning and distortion are minimized.

• Higher wheel speed and smaller diameter than conventional wheels

As steel or aluminum are used as the core materials, the wheels can be used at much higher speed than conventional wheels, eg. ≧80m/s. At higher wheel speed, the infeed rate can be increased along with longer wheel life and cycle time will be reduced.

• Dressings and downtime greatly decreased

Compared with conventional wheels, the dressing interval is extended. Especially for grinding machines with good rigidity and high power, the optimum performance of high cutting ability, high efficiency and excellent quality can be fully achieved.

• Adjustable roughness and removal rates requirement

By menas of change of dressing parameters, different roughness and removal rates requirements can be achieved. Namely, one wheel can be used for both rough and finish grinding.

• Easy for truing and dressing

The conditioning of vitrified bond wheels is easier than those of resin and metal bond wheels. Vitrified bond wheels only need one process, truing, to simultaneously complete truing and dressing which are normally two different procedures for resin and metal bond wheels. Also, vitrified wheels don’t have the drawback of electroplated ones whose abrasives are not fully utilized.

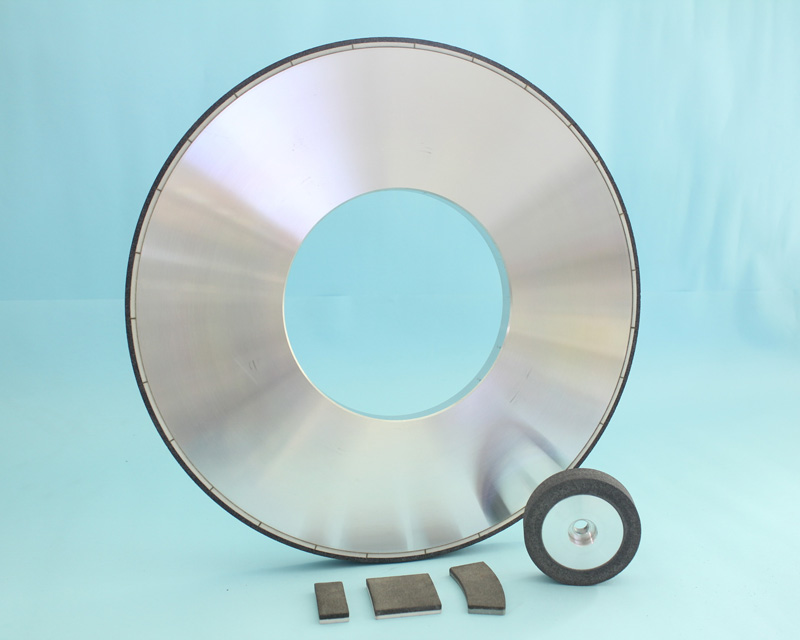

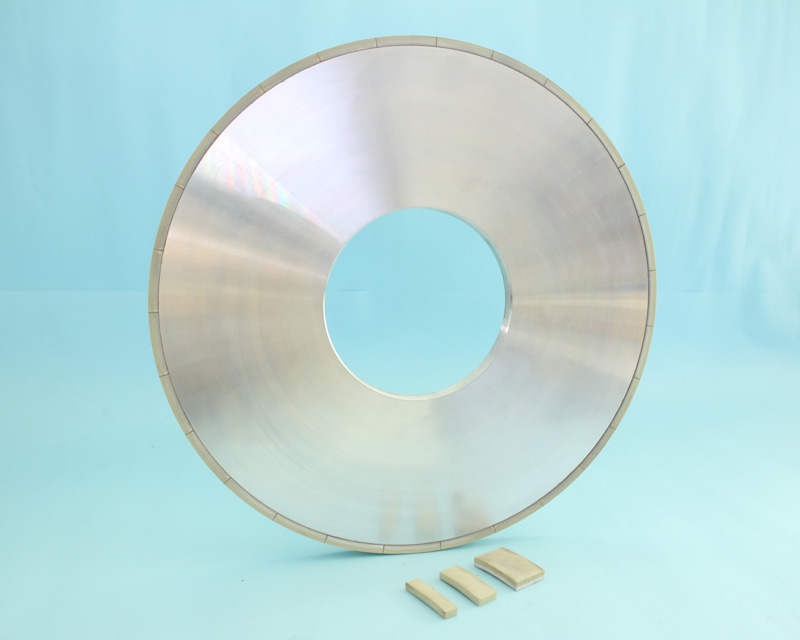

Segment Assembly Design

Segment Assembly Design provides us the flexibility to manufacture many sizes and shapes of wheels without imposing limitations. This unique manufacturing method helps to achieve grinding requirement for higher accuracy as well as to save the costs of hub for the customers and to get faster turnaround as the wheel hubs can be re-used. We begin with a custom design of the abrasive section of the wheel utilizing individual segments, and then use a precision assembly process to create the finished product. This design allows us with the perfect tool to manufacture intricate forms based upon customers’ requirements. Segment Assembly Design offers an effective solution and savings in both dollars and time, by re-using an existing wheel hub and mounting new abrasive segments to it. And if the wheel is damaged accidentally, we can replace only the damaged segments and restore the wheels to their utilization. Please contact us regarding the possibility for re-using your wheel hubs.

Applications for Vitrified Bond CBN Wheels

• Automotive and motorcycle parts: camshaft, crankshaft, valve, powertrain and transmission parts

• Engine building

• Camshaft and crankshaft: profile and journal grinding

• Peel grinding

• Motor shafts

• Punch: OD and form grinding

• Gear and cam: profile and journal grinding

• Roller for transmission purpose

• Bearing: groove OD grinding and needle centerless grinding

• Ship building

Applications for Vitrified Bond Diamond Wheels

• Tungsten carbide punch and mold parts

• Precision ceramic parts: aluminum oxide, zirconia, silicon carbide, silicon nitride

• Tungsten carbide drill

• Quartz parts

• Tungsten carbide molds, dies and jigs for electronics

• Spraying forming parts