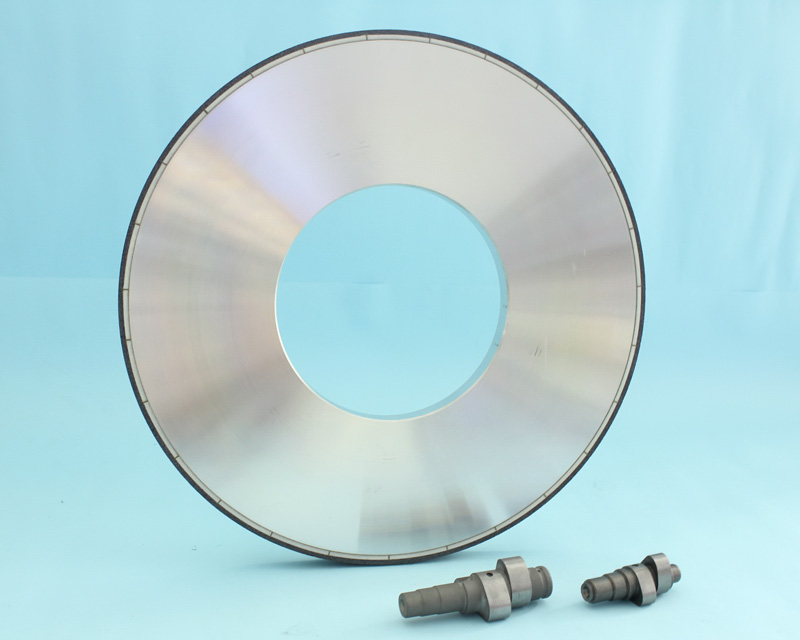

Camshaft & Crankshaft ━External Cylindrical Grinding Profile and Journal Grinding

Features

• High hardness, high thermal conductivity

With these characteristics of CBN and the existence of porosity which will facilitate the chip clearance, the grinding resistance and temperature are lowered, which will minimized the possibility of burning and distortion.

• High wheel speed, smaller wheel diameters than conventional wheels

Using steel material as the core will help the use of higher grinding speed than those for conventional wheels, for example ≧60m/s, resulting in higher infeed rate and shortened cycle time. In addition, with the feature of much more wear resistance, CBN wheels can use a smaller diameter which will promote the use of downsized grinding machines.

• Long dressing interval

Compared with conventional wheels, CBN ones can prolong the dressing intervals for 200~300 times that will reduce the dressing amounts and the time for changing wheels and machining down time.