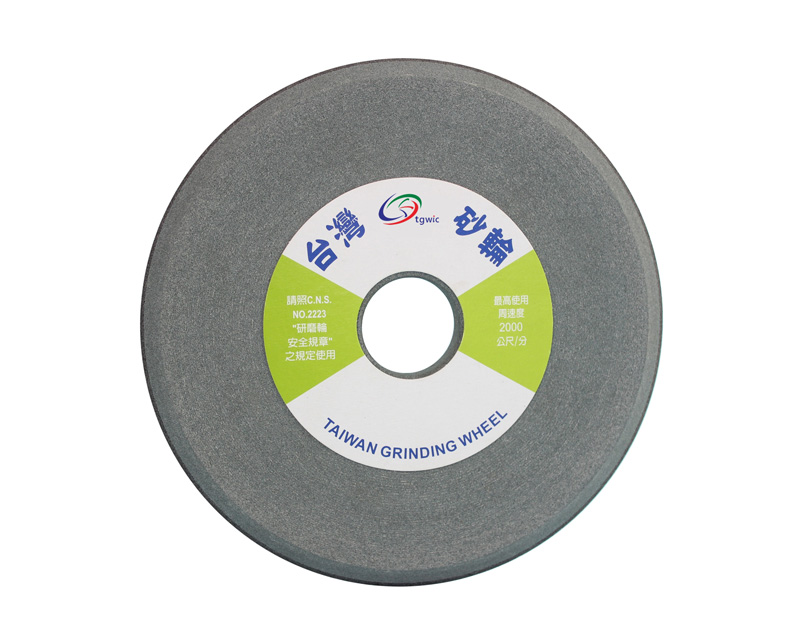

Internal Grinding-Vitrified Bond Precision Wheels

According to the grinding methods, it is classifiedas follows:

1. Internal grinder: The workpiece is chucked and rotating.

2. Jig grinder: The workpiece is chucked but not rotating.

In accordance with the workpiece shapes, there are the following 3 types:

1. Through hole: Wheel can pass through the internal hole of workpiece freely.

2. Blind hole: Wheel can only pass one side of the internal hole of workpiece.

3. Face: The face of workpiece sometimes has to be ground.

Internal grinding is used to meet the following requirements simultaneously.

◆ Consistent bore diameter

◆ Roundness

◆ Cylindricity

◆ Roughness

Depending on different materials of workpiece, different abrasives should be selected.Especially for hardened steels such as SKD11, HSS, SKD61, SCM21, SCM400 series, and SUS400 series, if used on high rigidity grinding machines operating at surface speed ≥45m/s , the following objectives can be attained simultaneously.

◆ High Cpk for size precision

◆ Consistent roundness & cylindricity

◆ Long dressing interval

◆ Short cycle time

Applicable Industries

• Parts manufacturing in automotive & motorcycle: gear, cylinder, CVJ, injection nozzle

• Tool & cutter: hob, gear, cam

• Bearing: bore and track grinding

• Mold and die used in the electronic industry

• Other mechanical parts manufacturing

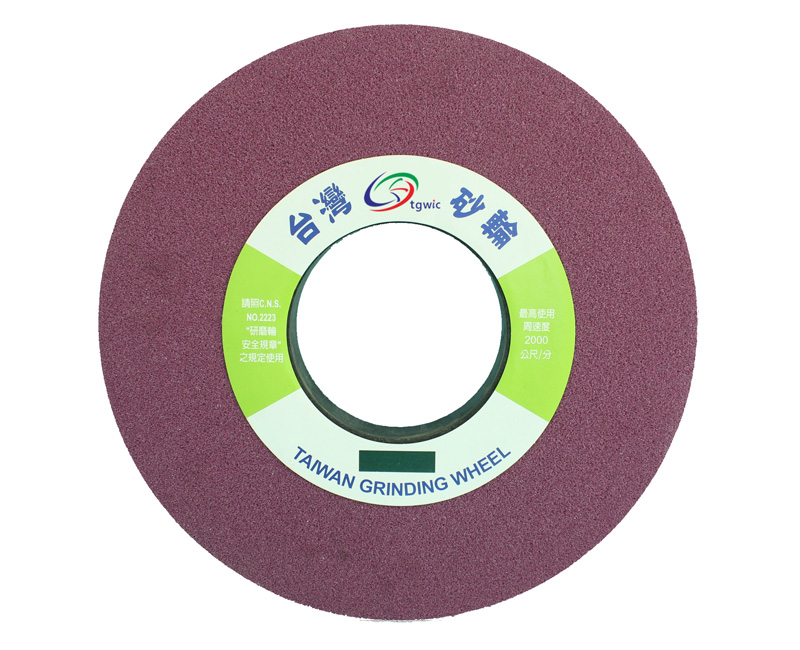

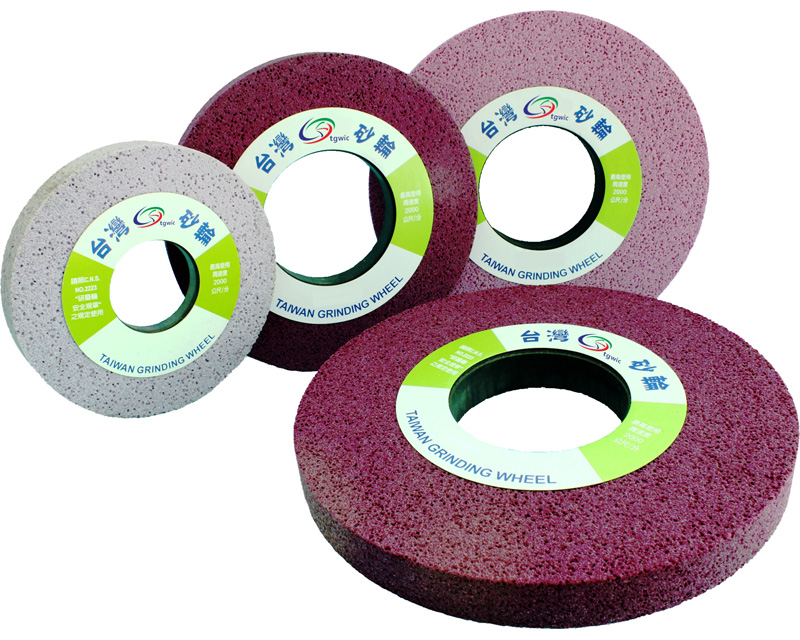

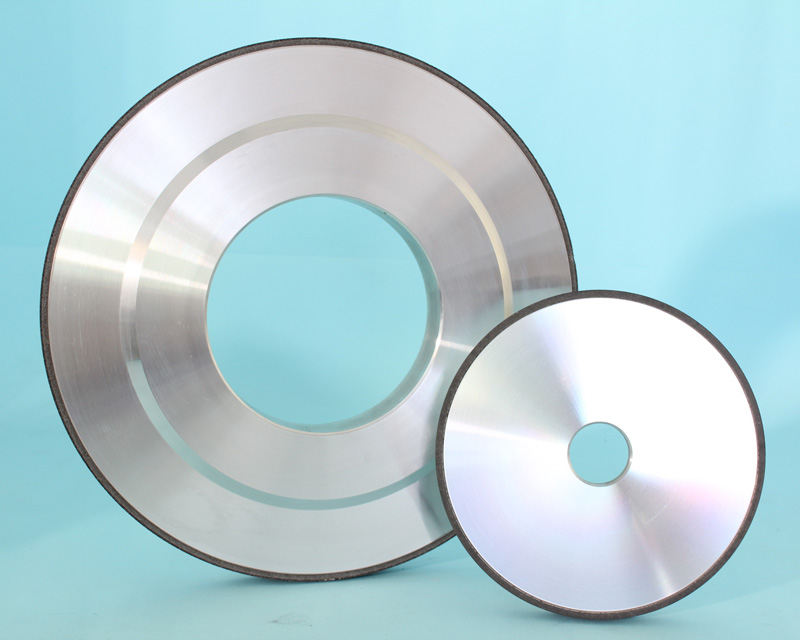

External Cylindrical & Centerless Grinding

Cylindrical wheels are most often used when the part is held between centers and in chucks. There are three methods of cylindrical grinding: plunge, traverse and angular.

1. Plunge grinding-wheel is thrust or plunged into the part

2. Traverse grinding-wheel moves across the part

3. Angular grinding-wheel infeed into the part at an angle

If used in grinding machines with high power & high rigidity as well as at higher surface speed such as 45m/s, the wheels can achieve more consistent size precision, less dressing, higher efficiency and higher cutting ability.

Applicable Industries

• Engine manufacturing in automotive & motorcycle industries: camshaft, crankshaft,

transmission shafts, etc.

• Shafts for motors

• Gear & cam

• Roller for transmission & conveyor

• Bearing

• Shipbuilding

• Aerospace

• Ball screw

• Toolroom

Product Features

Features |

Benefits |

|

|---|---|---|

‧Ceramic aluminum oxide (micro-crystalline) ‧Highest hardness & toughness among Al2O3 ‧Self-sharpening ‧Used with durable bond |

‧Higher removal rate, lower grinding temperature ‧2X~5X longer wheel life than other abrasives ‧Longer dressing intervals ‧Good form holding ‧Good free cutting ability ‧Applicable for materials with high hardness or high tensile strength, Ex: alloy, tool and high speed steels |

|

Features |

Benefits |

|

|---|---|---|

‧ Mono-crystalline ‧Hard & tough |

‧Good free cutting ability, versatile ‧Long dressing intervals and consistent size precision ‧Good form holding ability ‧Suitable for materials with medium to high hardness |

|

Features |

Benefits |

|

|---|---|---|

‧Angular shape ‧Harder & tougher than PA |

‧Free cutting ability similar to SA ‧Applicable to hardened steels such as high carbon steel, alloy steel and high speed steel |

|

Features |

Benefits |

|

|---|---|---|

‧Friable than DA ‧Tougher than WA |

‧Suitable for steels with hardness ≤HRC55 ‧Mainly for medium removal rate |

|

External Cylindrical (OD) Grinding Wheels for Surface Speed 45m/s

These wheels are suitable for grinding machines with high rigidity operating at 45m/s. Ex: TOYODA, SHIGIYA, NTC, KONDO, STUDER, LANDIS, etc. Higher efficiency, less dressing, better finish, longer wheel life and consistent size precision can be attained simultaneously.

Applicable Materials |

Grit Sizes |

Sizes |

Remark |

|---|---|---|---|

SKD, SCM, SNCM, carbon steel, cast iron, HSS, etc. With or without heat treatment. |

46 |

D T 12 ~ 160 |

For high rigidity grinding machines operating at 45m/s. |

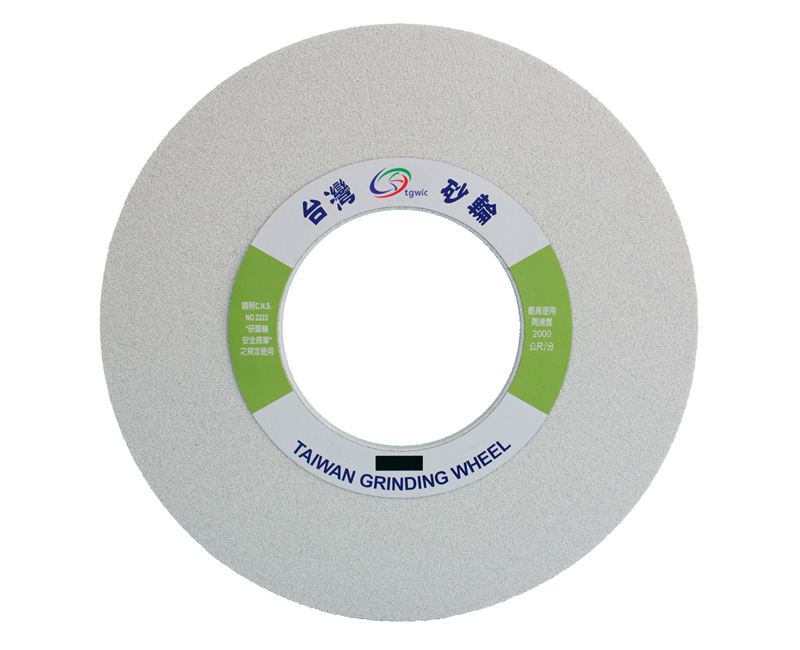

Surface, Form, Creepfeed Grinding-Vitrified Bond Precision Wheels

Surface grinding is the grinding of flat surface in which the wheel moves past the workpiece in a flat plane, or vice versa. Surface grinding applications range from heavy rapid stock removal, to precision contour grinding. By means of appropriate abrasives mixed with optimum bond, these wheels are versatile and suitable for various materials. High efficiency, stable & high precision for size control, good free cutting ability and long dressing intervals. If used with our proprietary “controlled porosity” technology, high porosity structure (structure: W) can be imparted into the wheels to further achieve higher removal rate.

Applications

• Molds and dies. Ex: Molds for pressing, plastic injection. Casting molds for aluminum, zinc, magnesium.

• Mechanical parts used in sewing & knitting machines.

• Machine tool: slideway, guideway, slot, linear guideway & block.

• Sharpening knives, blades, razors and cutlery.

• Producing flat stock.

常用粒度&尺寸

D |

T |

H |

Types |

|---|---|---|---|

180 205 |

6 8 13 16 19 25 |

31.75 50.8 |

1 5 7 10 10-1 |

305 355 405 |

25 32 38 50 65 |

76.2 101.6 127 |

|

455 510 610 |

38 50 75 100 |

127 152.4 203.2 |

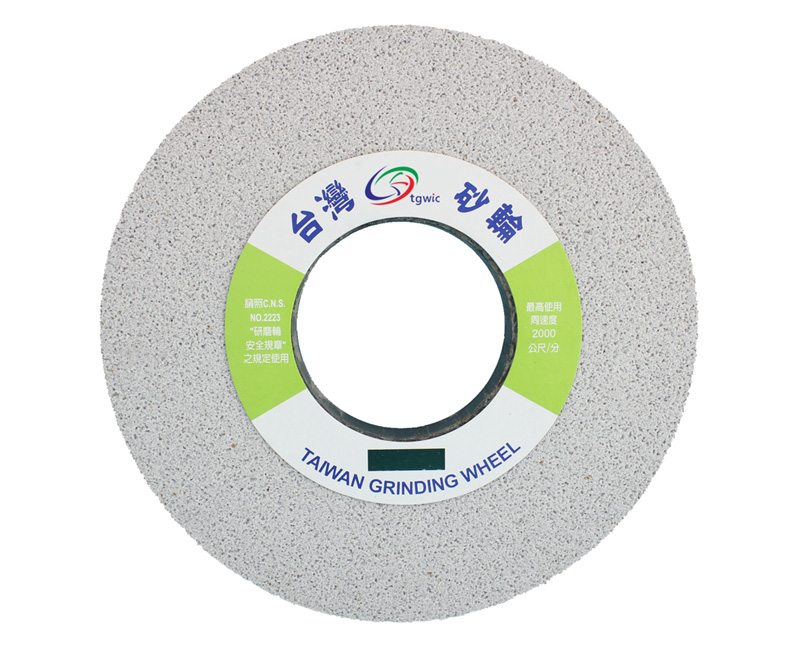

High Porosity Structure for Surface Grinding: DA, PA

High Porosity Structure is developed under our proprietary technology--controlled porosity. It is mainly used for hard-to-grind materials as well as heat sensitive materials, Ex: hardened steel, Inconel, nickel based alloy, cobalt based alloy and stainless steel. The free cutting ability and heat dissipation effect are very good. It’s suitable for higher depth of cut or higher removal rate such as creepfeed grinding.

PA: for medium to heavy removal rate

DA: for heavy removal rate

Features |

Benefits |

|---|---|

High Porosity |

• Increased chip clearance and maximum coolant flow • Decreased wheel loading • Cool cutting--wet or dry in heat sensitive applications |

Durable Bond |

• Increased grain holding strength • Less dressing and longer wheel life |

Higher Depth of Cut |

• Increased grinding efficiency • Consistent cutting ability at high removal rate |

Applicable Material & Wheel Specification and Sizes

Applicable Material |

Grit Sizes |

Sizes |

Remark |

|---|---|---|---|

SKD, SCM, carbon steel, SUS, and other various hardened steels as well as difficult to grind materials. |

30 |

D: ø100 ~ ø 610 mm T: 19 ~ 150 mm |

The proprietary “high porosity structure” has good heat dissipation and free cutting ability. It’s applicable to higher depth of cut and heavy removal rate. |

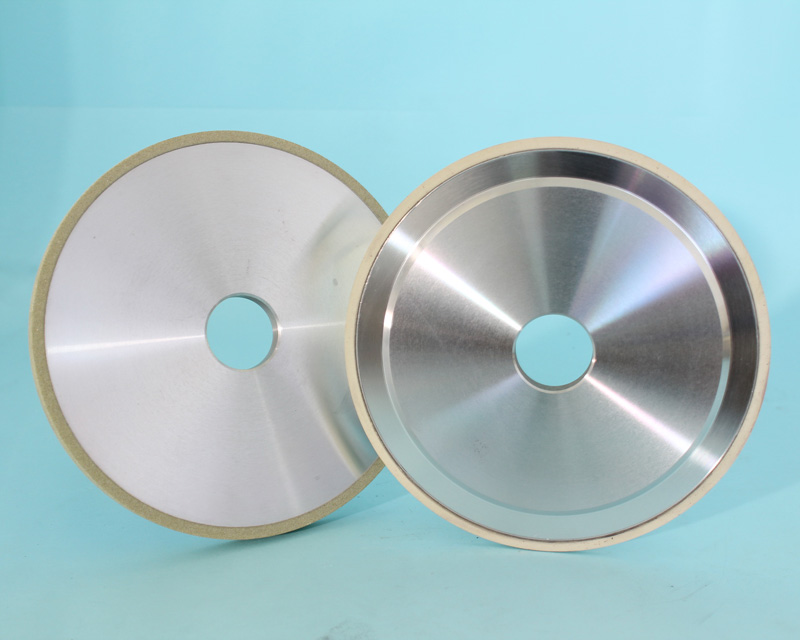

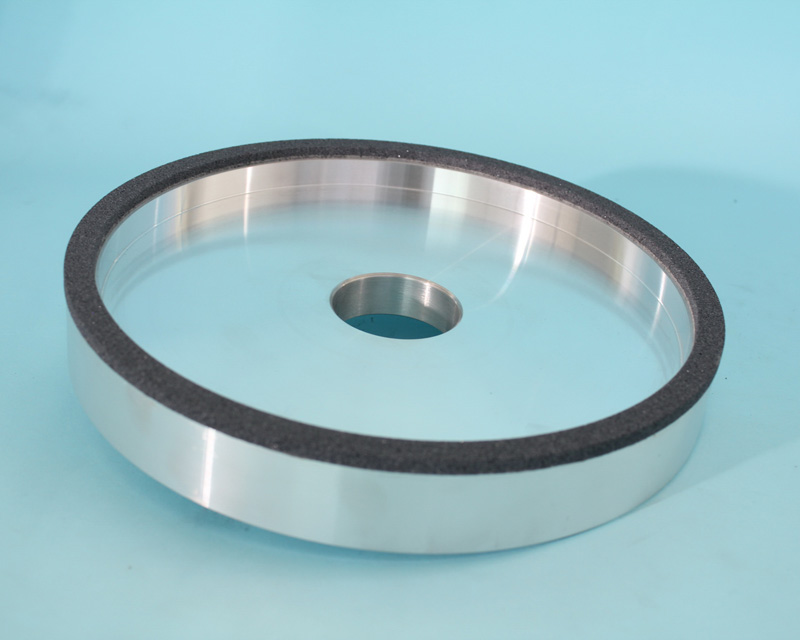

Surface, Form, Creepfeed Grinding-Vitrified Bond Diamond & CBN Wheels

Features

• Low grinding resistance, stable size accuracy, good finish

Optimum combination of abrasive and bond help easy chip clearance, stable size control and finish.

• One wheel for both rough and finish grinding

By means of change of dressing parameters, one wheel can be used for both rough and finish grinding in order to meet different requirements of roughness and removal rates.

• Easy for dressing

Single point diamond or impregnated dressing tools can be used for dressing.

br>

• Excellent corner holding for form grinding

Can be custom made for fine grit size and small corner while still maintaining good cutting ability.

• Strong bond holding strength and high porosity, very suitable for creepfeed grinding

With the very high hardness and thermal conductivity of superabrasives, when used in creepfeed grinding, the wheels will greatly reduce the effect of grinding heat induced to the workpiece especially suitable for materials with low thermal conductivity such as aerospace materials.

Applications for Vitrified Bond CBN Wheels

• Injection system parts

• Rocker arm form grinding

• Molds and dies

• Electric clippers and razors (vertical spindle)

• Linear guideway surface and form grinding

• Aerospace parts creepfeed grinding

• Difficult-to-grind materials creepfeed grinding, such as Inconel, nickel based and cobalt based alloy, stainless steels

Applications for Vitrified Bond Diamond Wheels

• Tungsten carbide punch molds

• Wear resistant parts: PCD (polycrystalline diamond) and PCBN (polycrystalline CBN), monocrystalline diamond

• Tungsten carbide and cermet inserts