Honing Stone

Purposes of honing:

•Size accuracy

•Roundness

•Cylindricity

•Surface finish

•Surface curve required such as plateau honing

Features

• Stable cutting ability without clogging, loading, glazing

• Short cycle time and long stone life

• Stable surface finish without irregular scratch

• Various stone specification suitable for both soft and hard materials

• Versatile bond types to suit different applications

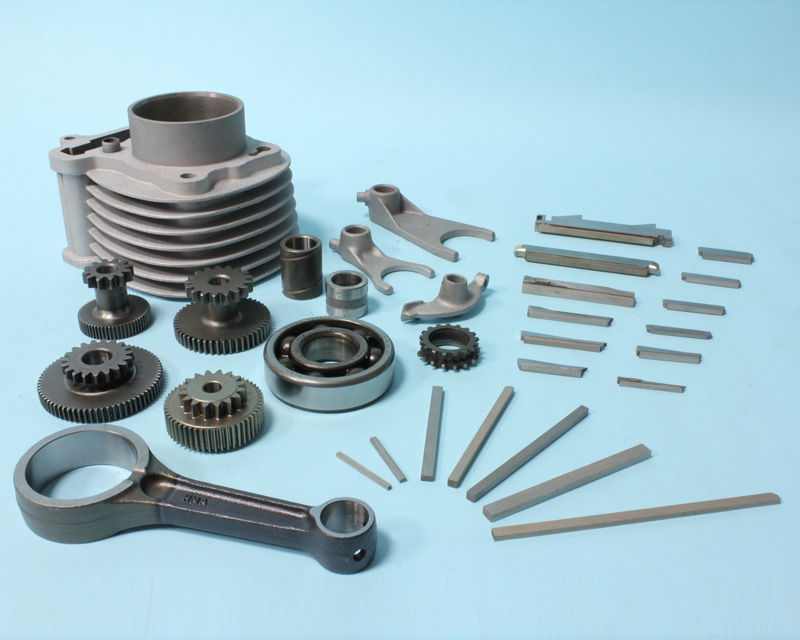

Applications for Metal Bond CBN Honing Stone

• Engine building: cylinder bore, cylinder sleeve, connecting rod, rocker arm, gear

• Automotive: steering assembly, carburetor, shock absorber

• Hydraulics: gear pump, carrier bush, tube honing

• Compressor parts: cylinder bore

• Brake system: ABS parts, brake drum, master brake cylinder

Applications for Metal Bond Diamond Honing Stone

• Ceramics parts

• Tungsten carbide bush

• Cast iron cylinders

• Ceramic cylinders: SiC-Ni

• Hypereutectic aluminum cylinders

For Honing Machines

• Aoba

• Hamano

• Chishima

• Micromatic

• Engis

• Nagel

• Fuji

• Nissin

• Gehring

• Sunnen

• General Hone

• Toyo

Common Used Sizes

L |

W |

T |

|---|---|---|

30 |

2 |

1.5 |

30 |

2 |

2 |

30 |

2 |

2.5 |

30 |

2.5 |

2 |

30 |

2.5 |

2.5 |

30 |

3 |

2 |

30 |

3 |

2.2 |

30 |

3 |

2.3 |

30 |

3 |

2.5 |

30 |

7 |

3 |

40 |

2.5 |

2 |

55 |

3 |

2.5 |

60 |

3 |

4 |

75 |

4 |

4 |

75 |

4 |

4.2 |

75 |

4 |

5 |

80 |

3 |

4 |

80 |

4.5 |

3 |

90 |

4 |

4 |

90 |

4 |

5 |

100 |

4 |

4 |

110 |

4 |

4.5 |

120 |

3 |

2.5 |

120 |

3 |

4 |

120 |

3 |

4.5 |