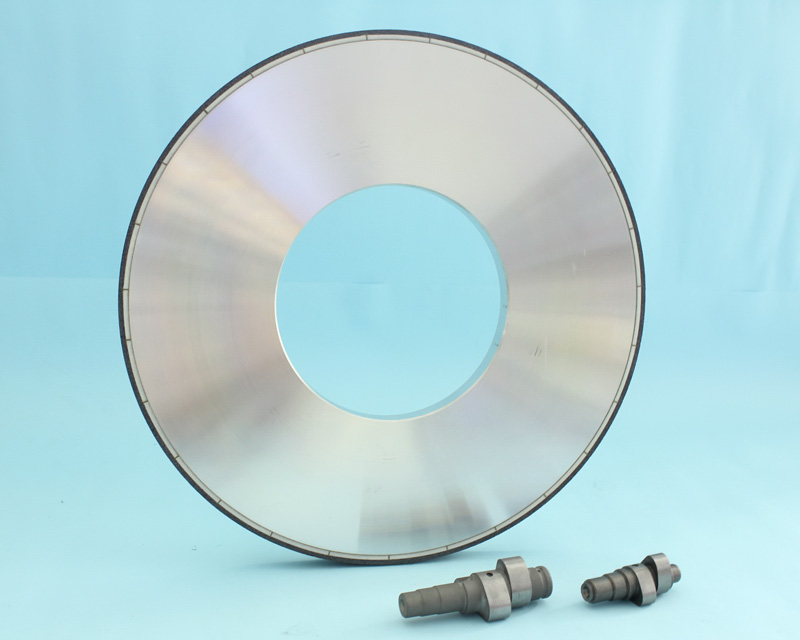

Vitrified Bond CBN Wheels

Features

• High hardness, high thermal conductivity

With these characteristics of CBN and the existence of porosity which will facilitate the chip clearance, the grinding resistance and temperature are lowered, which will minimized the possibility of burning and distortion.

• High wheel speed, smaller wheel diameters than conventional wheels

Using steel material as the core will help the use of higher grinding speed than those for conventional wheels, for example ≧60m/s, resulting in higher infeed rate and shortened cycle time. In addition, with the feature of much more wear resistance, CBN wheels can use a smaller diameter which will promote the use of downsized grinding machines.

• Long dressing interval

Compared with conventional wheels, CBN ones can prolong the dressing intervals for 200~300 times that will reduce the dressing amounts and the time for changing wheels and machining down time.

Wheel Dimensions & Types

D |

T |

X |

H |

|---|---|---|---|

100 |

15 |

5 |

10 |

250 |

12 14 18 20 22 25 |

3 |

152.4 |

350 |

6 8.8 14 15 16 18 20 |

3 |

152.4 |

510 |

18 |

3 |

203.2 |

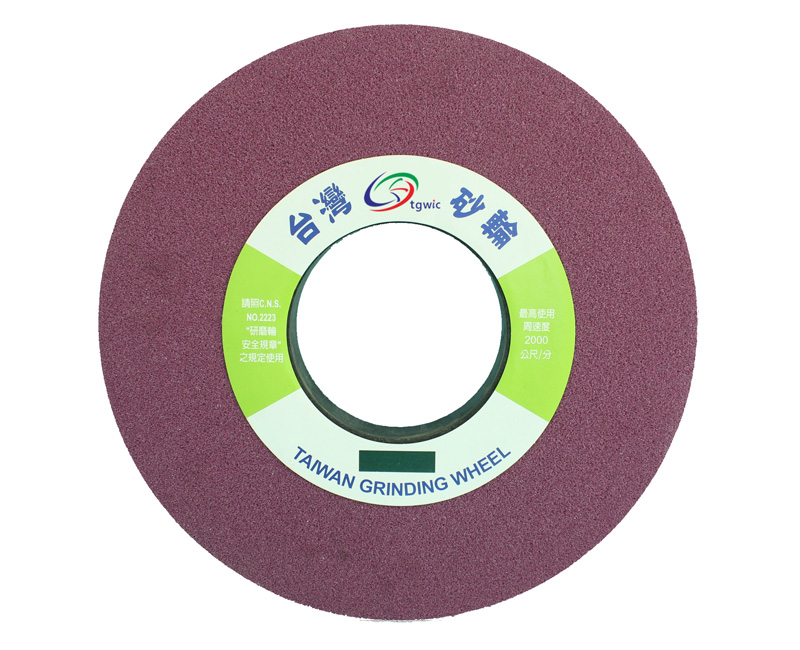

External Cylindrical & Centerless Grinding

Cylindrical wheels are most often used when the part is held between centers and in chucks. There are three methods of cylindrical grinding: plunge, traverse and angular.

1. Plunge grinding-wheel is thrust or plunged into the part

2. Traverse grinding-wheel moves across the part

3. Angular grinding-wheel infeed into the part at an angle

If used in grinding machines with high power & high rigidity as well as at higher surface speed such as 45m/s, the wheels can achieve more consistent size precision, less dressing, higher efficiency and higher cutting ability.

Applicable Industries

• Engine manufacturing in automotive & motorcycle industries: camshaft, crankshaft,

transmission shafts, etc.

• Shafts for motors

• Gear & cam

• Roller for transmission & conveyor

• Bearing

• Shipbuilding

• Aerospace

• Ball screw

• Toolroom

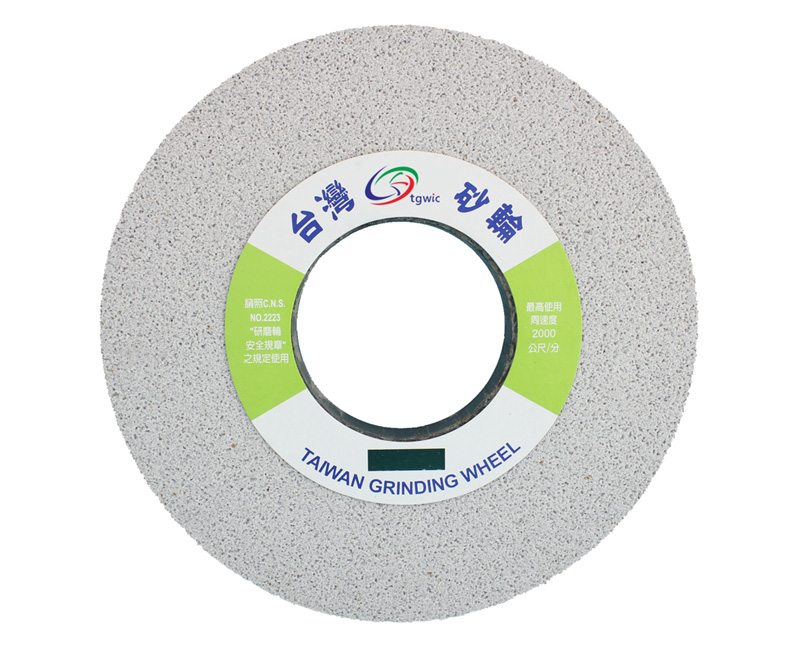

Product Features

Features |

Benefits |

|

|---|---|---|

‧Ceramic aluminum oxide (micro-crystalline) ‧Highest hardness & toughness among Al2O3 ‧Self-sharpening ‧Used with durable bond |

‧Higher removal rate, lower grinding temperature ‧2X~5X longer wheel life than other abrasives ‧Longer dressing intervals ‧Good form holding ‧Good free cutting ability ‧Applicable for materials with high hardness or high tensile strength, Ex: alloy, tool and high speed steels |

|

Features |

Benefits |

|

|---|---|---|

‧ Mono-crystalline ‧Hard & tough |

‧Good free cutting ability, versatile ‧Long dressing intervals and consistent size precision ‧Good form holding ability ‧Suitable for materials with medium to high hardness |

|

Features |

Benefits |

|

|---|---|---|

‧Angular shape ‧Harder & tougher than PA |

‧Free cutting ability similar to SA ‧Applicable to hardened steels such as high carbon steel, alloy steel and high speed steel |

|

Features |

Benefits |

|

|---|---|---|

‧Friable than DA ‧Tougher than WA |

‧Suitable for steels with hardness ≤HRC55 ‧Mainly for medium removal rate |

|

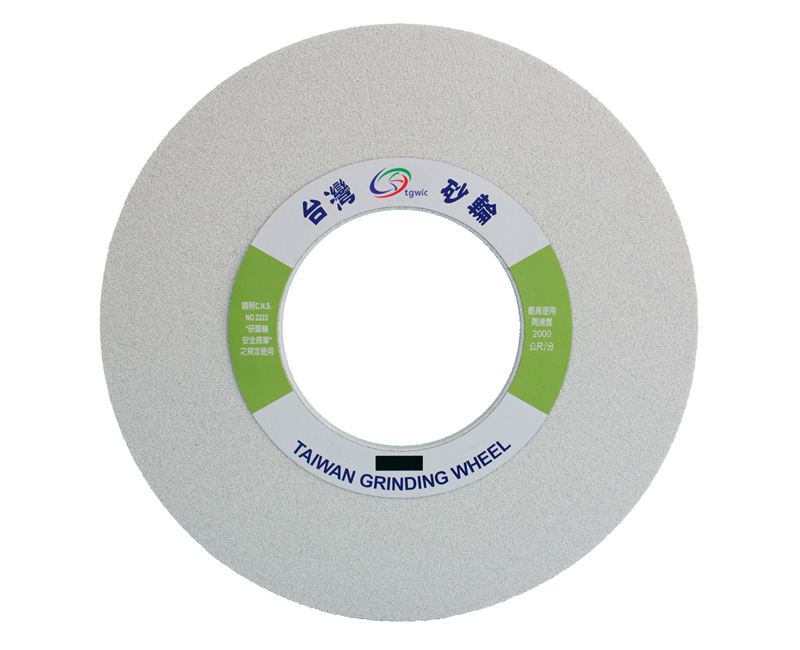

External Cylindrical (OD) Grinding Wheels for Surface Speed 45m/s

These wheels are suitable for grinding machines with high rigidity operating at 45m/s. Ex: TOYODA, SHIGIYA, NTC, KONDO, STUDER, LANDIS, etc. Higher efficiency, less dressing, better finish, longer wheel life and consistent size precision can be attained simultaneously.

Applicable Materials |

Grit Sizes |

Sizes |

Remark |

|---|---|---|---|

SKD, SCM, SNCM, carbon steel, cast iron, HSS, etc. With or without heat treatment. |

46 |

D T 12 ~ 160 |

For high rigidity grinding machines operating at 45m/s. |