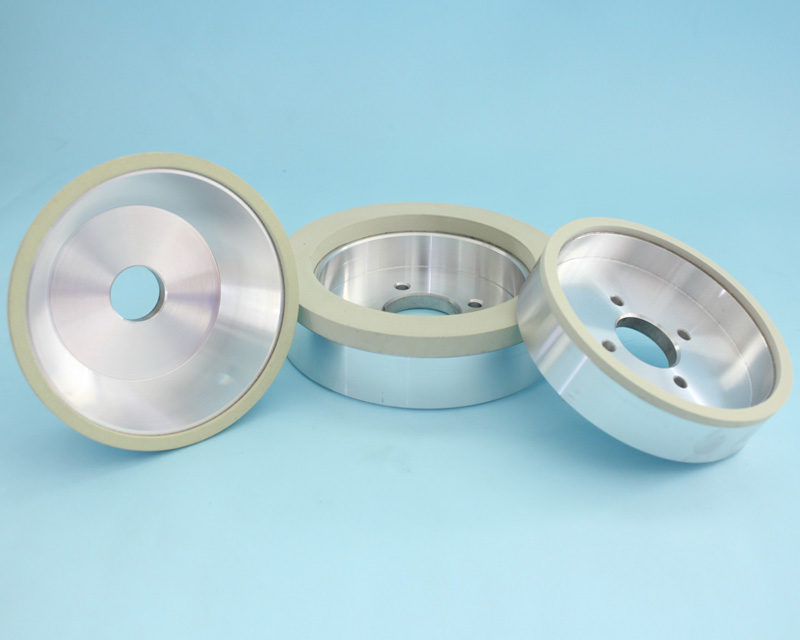

Vitrified Bond Diamond Wheels

Materials: Tungsten Carbide, Cermet, Ceramics

Features

• Strong bond holding strength, 5 times longer wheel life

Vitrified bond have good holding strength and the wheel life can achieve 5 times of resin bond ones. Wheel changing is reduced and efficiency increased.

• Porosity facilitate the chip clearance and coolant flow

Promote lower grinding resistance and less grinding heat. Fatigue strength ofworkpieces is increased.

• Good cutting and self-sharpening abilities, high accuracy for workpiece size and shapes

The maintaining of cutting ability is stable, without the phenomena of prematurely dislodging and dulling. The sizes of workpieces are stable and high accuracy is assured.

• Versatile

Based on the above advantages, one grit size can be used for both rough and finish grinding. Grit size finer than resin bond can be used while achieving the same surface finish and 5 times wheel life.

Applications

• Tungsten carbide, cermet, ceramics: inserts, turning tools

• Tungsten carbide, cermet, ceramics: band saw, face/top/side grinding of circular saw blades

Application Example

Workpiece |

Carbide-tipped circular saw blades |

|||

|---|---|---|---|---|

Parameters position |

rpm |

wheel speed m/s |

infeed rate mm/s |

depth of cut mm |

Top |

4200 |

27 |

6 |

0.3~1.5 |

Face |

4200 |

44 |

6 |

0.1 |

Side |

4000 |

25 |

2~6 |

0.15~0.2 |

Results |

Compared with resin bond wheels: 1.Lower grinding resistance 2.Less grinding heat 3.Shortening 30% cycle time 4.Better in size and shape accuracy 5.times longer wheel life |

|||